KraussMaffei and ELIX Polymers bring together expertise in injection moulding materials and technology

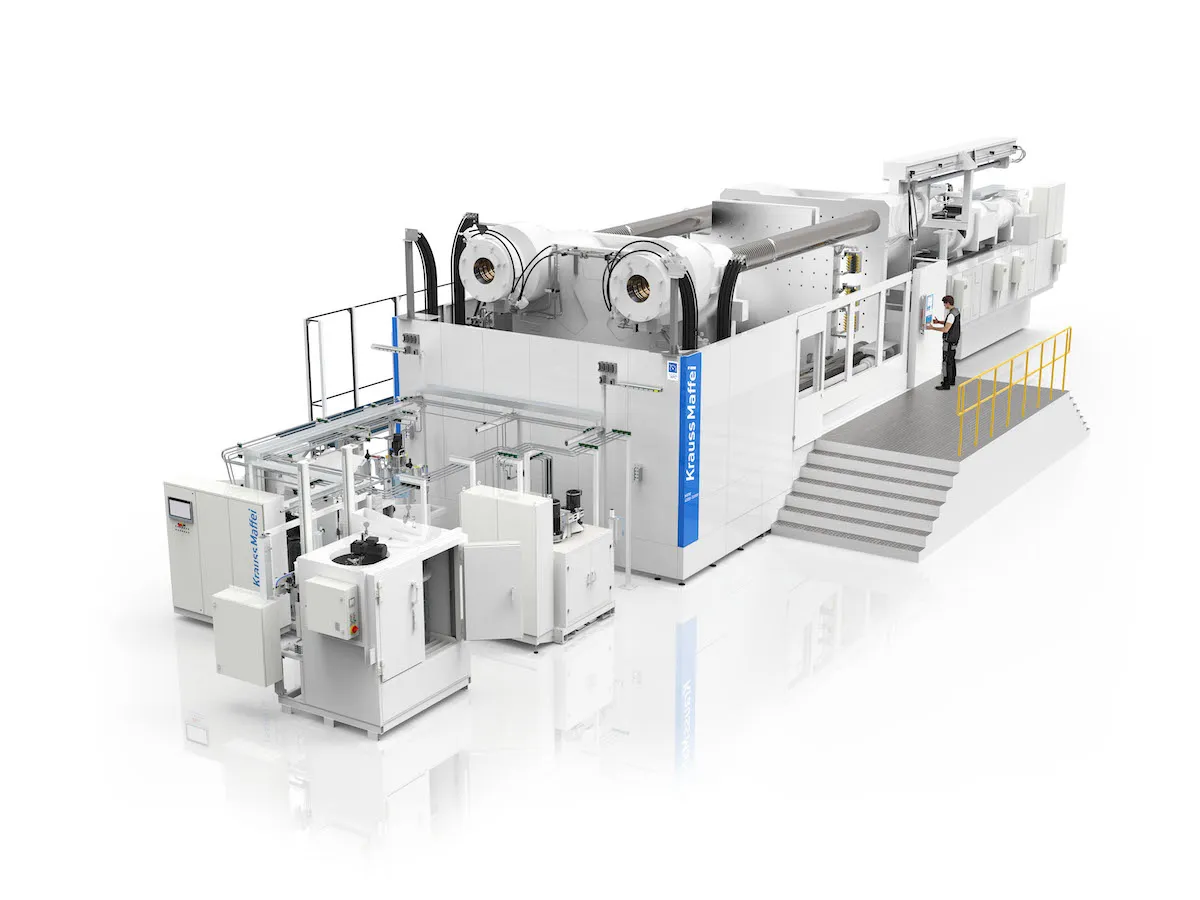

KraussMaffei and ELIX Polymers teamed up to promote the injection moulding of our more sustainable E-LOOP products at Chinaplas and Fakuma, using the innovative ColorForm and sandwich processes.

Sustainable materials: Injection using innovative processes

At the Chinaplas trade fair, we used our ELIX PC/ABS 5120MR as a basic carrier for phone cases, to which a flowable polyurethane (PUR) coating was applied. This combination offers excellent adhesion and surface quality, together with outstanding scratch, UV and chemical resistance.

At Fakuma, KraussMaffei injected our E-LOOP products at their stand using the sandwich process. Our mechanically recycled PC/ABS E-LOOP 5120MR was used for the core of the tortoise-shaped demo part. The visually high-quality blue outer shell was made from our chemically recycled ABS E-LOOP P2H-AT CR, available in various colours and with different percentages of circular and/or bio-based raw materials.

As Sinochem International companies, we’re stepping up our cooperation and joint work in various technical areas.

“As sister companies, ELIX Polymers and KraussMaffei work closely together. By combining our expertise in materials and injection moulding technology, we offer innovative solutions and engage with our customers as a unified team to ensure the best results for each project.”

Contact