DOWNLOAD THE DOCUMENT

Life Cycle Assessment (LCA) and Carbon footprint of ELIX products

Fill in the following fields and you will receive in your e-mail the download link

E-LOOP includes all of our circular economy initiatives in terms of products, design and services.

We want to be a catalyst for more efficient, locally-implemented short loops for ABS recovery.

Our aim is to be a global leader of reference in the market of highly specialised thermoplastics. With this mission, we've been contributing to the transition towards a circular plastics economy for years, as this is one of the pillars of our business strategy. We offer more sustainable solutions through strategies for the recovery of ABS or other by-products, increased recirculation and the establishment of partnerships throughout our value chain.

Circular plastics and responsible innovation are the strategic programmes of ELIX's sustainable solutions portfolio. Let's close the loop!

ASPIRATIONAL OBJECTIVE:

We understand sustainable advantage as the inclusion of greater recycled mechanical, chemical or renewable content in our products, or a reduction in the intensity of the material and therefore an improvement of our environmental footprint.

PRIORITY LINES OF ACTION:

Main actions completed in 2022:

ASPIRATIONAL OBJECTIVES:

ACTION PLANS:

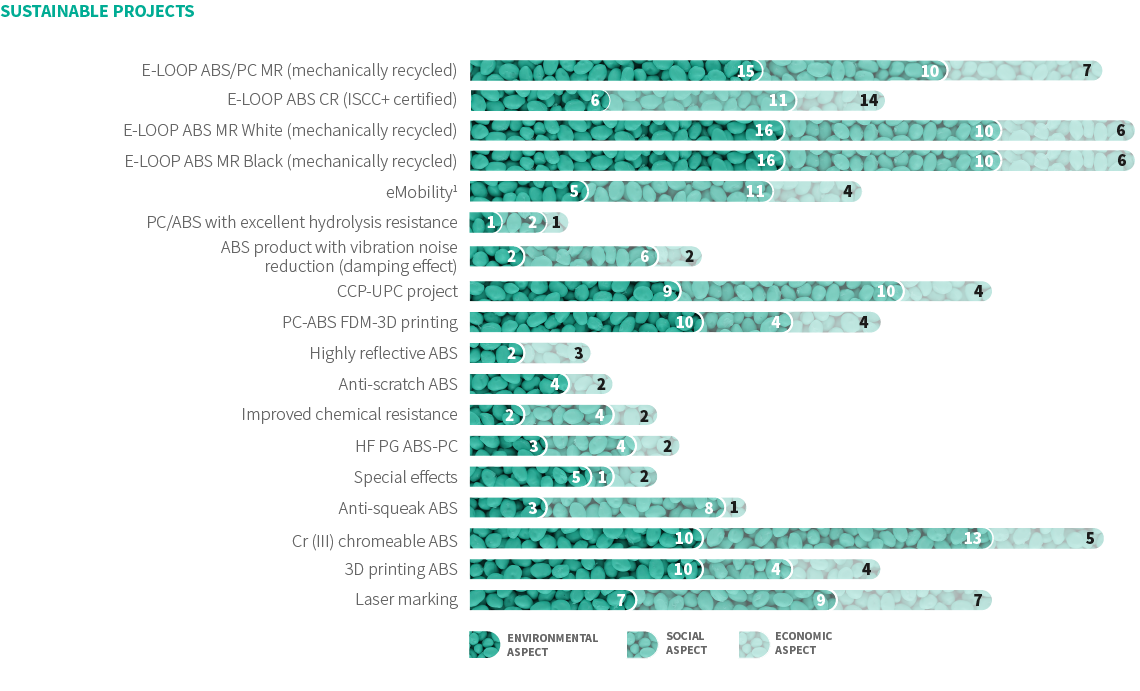

Our innovation strategy aims to develop a more sustainable product portfolio, increasing the amount of renewable and/or recycled raw materials for our products.

LIFE CYCLE ASSESSMENT

ELIX carries out a life-cycle assessment of its most sustainable E-LOOP solutions

Life-cycle assessment (LCA) is an internationally standardized methodology to assess the environmental impact associated with all stages of a product’s cycle.

ELIX has carried out a full LCA of its production based on ISO 14040 and ISO 14044 standards (cradle-to-gate analysis) taking into account transport to customer sites and direct (scope 1) and indirect (scopes 2 and 3) emissions. The aim of this analysis, validated by the Anthesis group, is to investigate the environmental performance of the most sustainable E-LOOP products and compare it with polymers of fossil origin.

Our LCA shows that mechanically and chemically recycled products can significantly reduce the environmental impact of the final product.

100 %

Recyclable products free of substances of high concern

2,84 %

LCA and carbon footprint calculation*

Carried out for all grades: virgin origin, ISCC (International Sustainability & Carbon Certification) materials and other raw materials.

We participate in international studies and projects that involve collaboration with other companies or organizations in our value chain.

Investment in R&D&i

Collaborative projects:

Internal projects:

In 2022 ELIX took part in a socio-technological project with Ayúdame3D, a Spanish socially responsible start-up that promotes the social value of technology through awareness programmes to help people with disabilities thanks to three-dimensional printing.

ELIX developed the recycled ABS raw material through 3D printing, a technology in which the company has extensive experience. The challenge was to offer a solution tailored to the project, incorporating the circular economy. In the manufacturing process, ELIX turned waste into a high value product (upcycling) thanks to the collaboration of the entire value chain and incorporating virtualization and new 3D technologies.

The project was possible thanks to the collaboration of Repsol, which donated 4,000 pieces of ABS plates to the association from computer equipment that would otherwise have been discarded, and of Leitat, a technology centre of excellence. Leitat manufactured coils from the raw material recovered by ELIX, for its subsequent printing using 3D technology and the manufacture of trésdesis, arms printed in three dimensions for the wrist, elbow or shoulder.

ELIX'S PORTFOLIO OF INNOVATIVE SOLUTIONS CONTRIBUTES TO THE TRANSITION TOWARDS A CIRCULAR ECONOMY. HAVE A LOOK!

NEED MORE INFORMATION?

DOWNLOAD THE 2024 SUSTAINABILITY REPORT