DOWNLOAD THE DOCUMENT

Life Cycle Assessment (LCA) and Carbon footprint of ELIX products

Fill in the following fields and you will receive in your e-mail the download link

Climate change is a global challenge we must face: adaptation and mitigation are two sides of the same coin which we incorporate into our sustainability strategy.

Our "Caring about climate" project represents a step forward in our commitment to the protection of the environment and the reduction of our environmental footprint, as well as an opportunity for us to adapt to climate-related risks.

CARING ABOUT CLIMATE

PROGRAMME OBJECTIVES

ACTION PLANS:

REDUCING OUR ENVIRONMENTAL FOOTPRINT

We have policies which define our commitment to environmental protection:

CERTIFICACIONES:

Reducing our environmental footprint means improving our energy performance and reducing our waste generation and water consumption.

Energy Efficiency Programme

Significant Environmental Aspects Programme

Project for minimising wastewater with high levels of TOC (total organic carbon)

In 2022, the Sustainable Operations Committee reviewed the strategic plan for reducing the carbon footprint and water consumption established in Programme 3 “Caring for climate". New initiatives have been studied and included in the plan to guarantee compliance with the aspirational goals.

WE ARE CONTINUING OUR ZERO PELLET LOSS PROGRAMME

ELIX forms part of a value chain of microplastics in the form of resin pellets and plastic powder. Though ELIX is not the direct cause of plastics being present in the sea, it does form part of the plastic life cycle, and therefore commits to being part of the solution.

To help face this global problem, it is important to act locally. Our Zero Pellet Loss Programme, which began in 2017 with the international programme Operation Clean Sweep (OCS), flakes and powder, and avoid the deposit of these materials into rivers and oceans, formalising our commitment to achieve SDG 14 for the protection of sea life.

At the same time, during 2021, we have carried out the following improvement measures:

Energy efficiency

In line with ISO 50001 requirements, ELIX has an energy efficiency programme that determines goals and their monitoring.

Some of the actions carried out in 2022 have been:

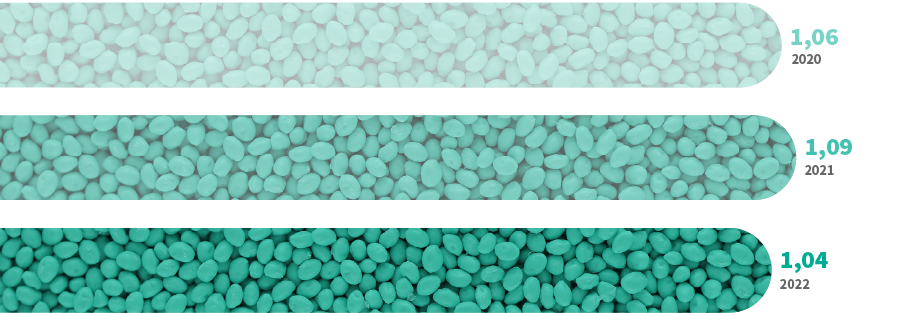

ENERGY INTENSITY (KWh*/t ABS PRODUCED)

*Types of energy included in the calculation: electricity, natural gas, steam, compressed air, 0 ºC cold, -2 ºC cold, nitrogen.

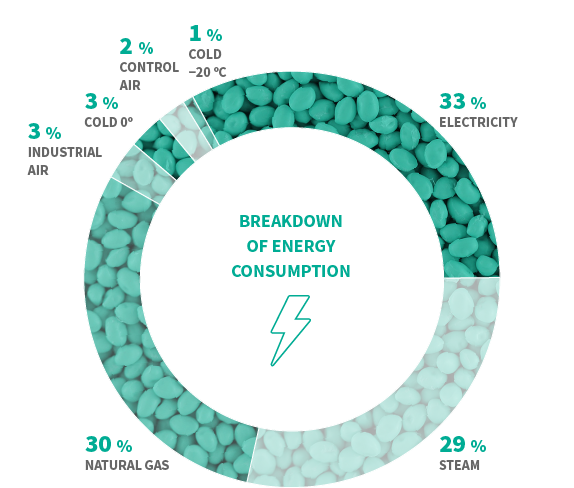

92% of our energy consumption is due to the use of electricity, steam and natural gas.

As of 1 October 2022, all of ELIX’s electricity consumption is covered by alternative sources to fossil fuels. All the electricity consumed by the Tarragona plant’s guarantee of origin is certified by the National Commission for Markets and Competition. This means a considerable reduction of the company’s CO2 emissions.

This measure takes us a step closer to achieving our priority objective, included in our Sustainable Operations programme, of reducing the carbon footprint associated with our operations. The use of renewable sources for the electricity supply to our facilities represents a significant milestone in our plan.

The carbon footprint

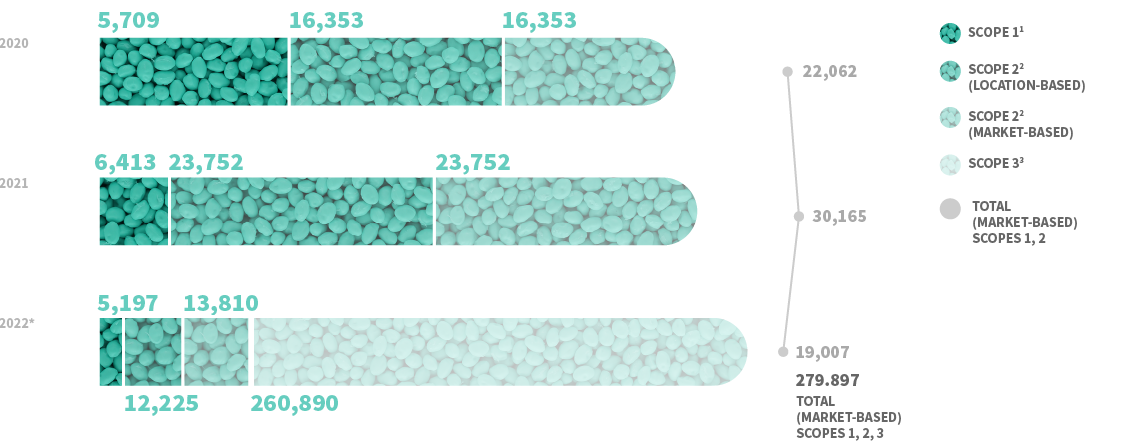

One of ELIX’s aspirational goals is to reduce the carbon footprint by at least 15% from 2017 to 2025.

To this end, we have been monitoring for years the environmental impact in terms of carbon of both our activity and our products.

With this monitoring and analysis of the results, we advance in the implementation of initiatives that allow a positive impact on the different environmental vectors

textos.2022_enviroment_04

1. Final results to be validated by the Government of Catalonia’s Voluntary Agreements Programme. These data do not coincide with those published in the 2022 Non-Financial Information Statement since these are preliminary data calculated prior to this report.

2. Includes emissions derived from the consumption of natural gas, petrol consumption by forklifts and corporate lease cars.

3. Includes emissions derived from consumption of electricity, cold and steam.

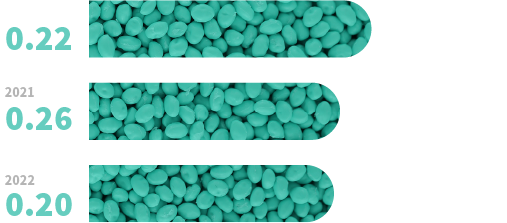

EMISSIONS INTENSITY

(tCO2eq Scope 1+2/t ABS PRODUCED + SALES)

1. Final results to be validated by the Government of Catalonia’s Voluntary Agreements Programme. These data do not coincide with those published in the 2022 Non-Financial Information Statement since these are preliminary data calculated prior to this report.

The carbon footprint of our organization

ELIX has once again renewed its adherence to the Voluntary Agreement Programme, of which it has been a part since 2016, promoted by the Catalan Office for Climate Change to reduce greenhouse gas emissions, beyond what is required by the legislation.

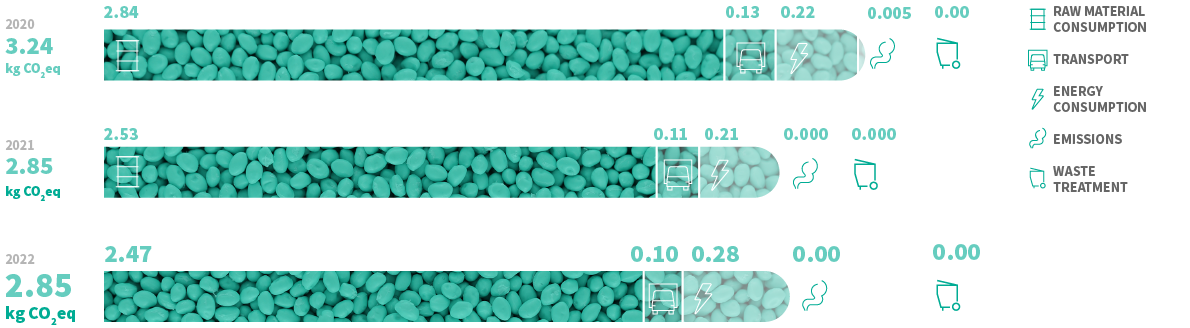

This past yearnwe calculatednthe carbon footprintnof our productnby carrying out a LifenCycle Assessmentn(LCA) based on thenISO 14040 and ISOn14044 standards.

ELIX studies the LCA of its products, with the most relevant monitoring indicators being the carbon footprint and water consumption.

We work to reduce product emissions through green energy measures, energy efficiency projects, initiatives in more sustainable forms of transport, substitution of non-renewable fossil fuel raw materials with more sustainable sources from chemical and mechanical recycling, bio-based materials (E-LOOP brand), etc.

We do so under the "cradle-to-gate” principle, that is to say measuring the impact from the extraction of the raw materials up to the delivery to the customers. The calculation takes into account three different scopes: scope 1 (direct emissions), scope 2 and scope 3 (indirect emissions).

CARBON FOOTPRINT OF THE PRODUCT

Includes sales of ABS intermediate products, offspec and scrap.

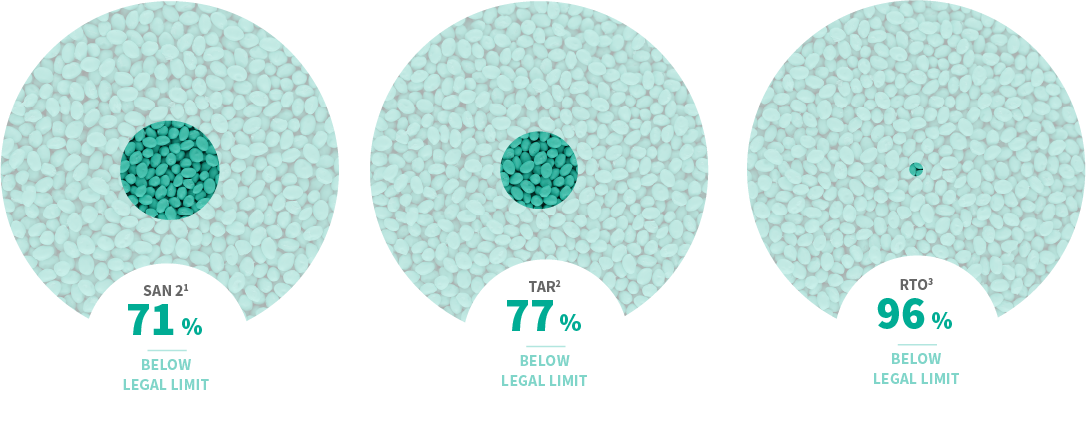

Other emissions

Contaminating atmospheric emissions of nitrogen oxide and carbon monoxide have hazardous consequences on the health of people and the environment.

NOX EMISSIONS

ANNUAL AVERAGE PER SOURCE FOR EACH PLANT (mg/Nm3)

LEGAL LIMIT

EMISSIONS IN 2020

1. Styrene copolymer and acrylonitrile production plant.

2. Waste gas treatment plant.

3. Thermal Oxidation Gas Treatment plant.

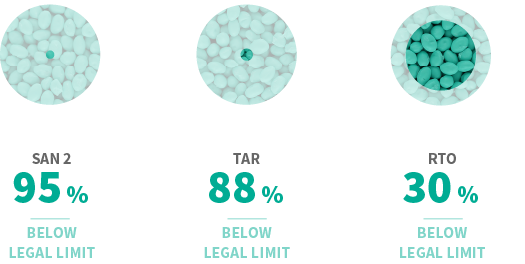

CO EMISSIONS

ANNUAL AVERAGE PER SOURCE BY PLANT (mg/Nm3)

Our emission levels of nitrogen oxide and carbon monoxide are much lower than current regulations permit.

ELIX has implemented the voluntary LDAR (Leak Detection and Repair) programme to control fugitive emissions, which consists of the inventory, detection and reduction of emissions of volatile organic compounds (VOC). Each year the inventoried points are monitored and any new detected points are added.

ELIX currently has a process in place to minimize the generation of waste, and it continues to work to improve waste management, controlling and identifying new aspects.

Within the framework of the circular economy, waste recovery is a fundamental aspect that is gaining even more relevance and something which we have been working on in recent years. We are gradually moving from a linear management model of collection and treatment by an authorized manager to a management model with a circular economy perspective, constantly seeking ways to recover and reuse our waste.

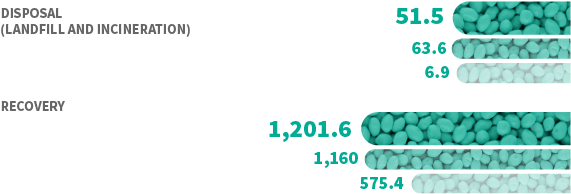

5.085 t

TOTAL GENERATED WASTE

24 %

VARIATION 2021-2022

3,51 %

TONNES OF TOTAL WASTE PER TONNE PRODUCED

3,51 %

VARIATION 2021-2022

More than 60% of our waste is recovered.

ABS production requires the use of dangerous chemical products and creates highly hazardous waste, which, if poorly managed, can pose serious health risks to people and cause environmental damage. Our protocols for monitoring and managing these products are stringent and comprehensive.

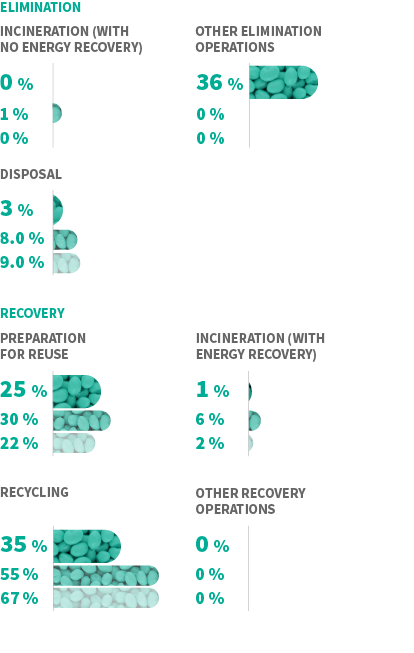

MAIN MANAGEMENT CHANNELS

(MANAGED TONNE PER CHANNEL/TONNE PRODUCED)

2022

2021

2020

We've maintained our downward trend in waste generation and have managed a 61 % reduction.

2022

2021

2020

Packaging waste prevention plan

Our packaging waste prevention plan is aimed at finding strategies to reduce the use of packaging in the field of distribution and logistics. For example, we have replaced certain packaging with tankers to ship our products within the European Union.

We have also implemented improvement actions to prevent and reduce their impact on the environment.

The decision on the type of packaging for the products we ship is unique and exclusive to the customer, which forces us to work together if we want to reduce the impact of the waste we generate outside our facilities.

Our water footprint

In the current context of climate change, predictions are that the Mediterranean coast will be one of the most affected areas. Water will become a scarce and precious good which will need to be distributed according to its different uses: domestic, agricultural and industrial.

We work to improve our efficiency in the use of this resource and to reduce the vulnerability of water drainage basins due to fresh water depletion. Our sustainability strategy 2030 sets the ambitious goal of reducing water consumption by 15% in comparison with 2017.

One of the objectives of the Climate Care program of ELIX’s Sustainability Strategy is to reduce water consumption by 15% from 2017 to 2025. For this reason, ELIX works to improve its efficiency in water use and reduce vulnerability of water basins in the face of freshwater depletion.

WATER CONSUMPTION

2022

VARIATION 2021-2022

103.080

TOTAL INDUSTRIAL WATER (m3)

-12 %

Water use efficiency:

1,01

WATER CONSUMPTION RELATIVE TO PRODUCTION (m3 /t ABS produced)

2%

67,4 %

INDUSTRIAL WATER CONSUMPTION WITH RESPECT TO BASE YEAR 2013

Packaging waste prevention plan

ELIX maintains its adherence to national and international initiatives in order to build a new business system capable of developing and sharing projects which have a positive impact on the environment. In this regard, in 2017 ELIX joined the international programme Operation Clean Sweep (OCS), known internally as the Zero Pellets Loss project.

Continued implementation of the Zero Pellets Loss programme

In 2022, the following actions were carried out in line with the action plan:

NEED MORE INFORMATION?

DOWNLOAD THE 2024 SUSTAINABILITY REPORT